Santa Rosa County FL custom home construction continues

January 5, 2013Call ParsCo for free consultation on building your dream home.

850-776-6265

Construction Management

Expand Navigation

Expand Navigation

Call ParsCo for free consultation on building your dream home.

850-776-6265

When constructing a project extra time and care in planning the construction around existing trees and foliage is essential. If done properly, salvaging an existing oak tree can add character and energy benefits to the project by providing a wind buffer and shade that will prove to be very valuable when evaluating the life cycle of the building.

Before construction begins, everyone involved attempts to do one thing: predict the future in order to minimize the risk of unforeseen events that might delay the project’s completion.

Owners, developers, contractors, subcontractors, architects, engineers, sureties, financial institutions, insurers, and vendors all want the project to be done well, and done on time. Why? Because one or more of them will have to eat the costs of substandard work or a delayed result, and that can be very expensive.

Construction delays are extremely dangerous: they can slow the project, or even bring it to a halt. Every construction project, from the smallest home addition to the tallest skyscraper, shares the same basic life cycle: (1) planning; (2) design; (3) construction; and (4) finalization.

Since severe weather conditions can be disruptive to construction, contractors typically obtain time extensions for weather days beyond normal conditions. Time extensions typically shift the completion date only, but in some cases it raises the cost of the project depending on extended overhead costs that the contractor may incur. Two of the most important factors that all parties are concerned with are completion date and total cost. Weather delays can affect both of these and often are a main point of contention between the parties on a project.

ParsCo’s construction managers focus on seven factors when analyzing a project that has experienced adverse weather conditions. They are: the definition of normal weather, weather thresholds, type of work, lingering days, criteria for lost days, lost days equivalent due to lost productivity, and work days lost versus calendar days lost.

ParsCo can conduct an analysis of an actual weather-caused delay claim by illustrating the impacts of those factors on the outcomes of the analysis. The prime contract should define anticipated weather delay days and their lingering days and provide threshold values for weather parameters to differentiate between predictable and unpredictable severe weather. The prime contract should also clearly define how a time extension is granted in calendar days as a result of work days lost, and also address how a time extension is granted due to inefficiency caused by unusually severe weather. ParsCo can also provide an analysis on the quantity of lost days due to weather and how it relates to lost productivity days.

On ParsCo construction projects, the ParsCo construction manager documents weather delays and report them on a consistent basis to the project team. This is because it is important to keep all parties in the loop. Owners of projects do not want to find out about a project delay 2 weeks before their projected grand opening. If good communication exists, regular construction meetings are conducted, and scheduling is updated to account for weather delays, then the project can run smooth and all parties can account for unforeseen/unknown conditions.

Amir Michael Fooladi

President/CEO

ParsCo, LLC

850.776.6265

Visit us on the web at www.pars-co.net

This communication, including attachments, is confidential, may be subject to legal privileges, and is intended for the sole use of the addressee. Any use, duplication, disclosure or dissemination of this communication, other than by the addressee, is prohibited. If you have received this communication in error, please notify the sender immediately and delete or destroy this communication and all copies.

https://oxblue.com/archive/0f1f8ae3fe7c7e4383b13a58d7e38c99/320×240.jpg?1351522849

ParsCo is an Equal Opportunity Employer and participates in E-Verify®.

Federal law requires all employers to verify the identity and employment eligibility of all persons hired to work in the

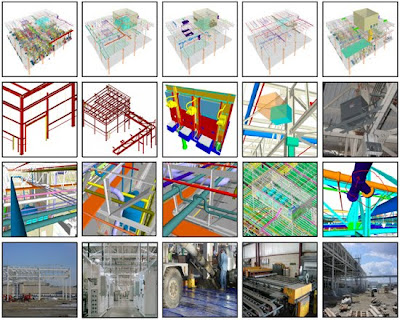

Building Information Models span the whole concept-to-occupation time-span. To ensure efficient management of information processes throughout this span, a ParsCo BIM manager should be appointed. The BIM manager is retained by a design build team on the client’s behalf from the pre-design phase onwards to develop and to track the object-oriented BIM against predicted and measured performance objectives, supporting multi-disciplinary building information models that drive analysis, schedules, take-off and logistics.

Participants in the building process are constantly challenged to deliver successful projects despite tight budgets, limited manpower, accelerated schedules, and limited or conflicting information. The BIM concept envisages virtual construction of a facility prior to its actual physical construction, in order to reduce uncertainty, improve safety, work out problems, and simulate and analyze potential impacts. Sub-contractors from every trade can input critical information into the model before beginning construction, with opportunities to pre-fabricate or pre-assemble some systems off-site. Waste can be minimised on-site and products delivered on a just-in-time basis rather than being stock-piled on-site.

Quantities and shared properties of materials can be extracted easily. Scopes of work can be isolated and defined. Systems, assemblies and sequences can be shown in a relative scale with the entire facility or group of facilities. BIM also prevents errors by enabling conflict or ‘clash detection’ whereby the computer model visually highlights to the team where parts of the building (e.g.: structural frame and building services pipes or ducts) may wrongly intersect.

All project partners – different design disciplines, the customer, contractor, specialists and suppliers – use a single, shared 3D model, cultivating collaborative working relationships. This ensures everyone is focused on achieving best value, from project inception to eventual decommissioning.

BIM makes possible swift and accurate comparison of different design options, enabling development of more efficient, cost-effective and sustainable solutions.

Through deployment of new generative modelling technologies, solutions can be cost-effectively optimised against agreed parameters.

Projects can be visualised at an early stage, giving owners and operators a clear idea of design intent and allowing them to modify the design to achieve the outcomes they want. In advance of construction, BIM also enables the project team to ‘build’ the project in a virtual environment, rehearsing complex procedures, optimising temporary works designs and planning procurement of materials, equipment and manpower.

Time savings, up to 50%, can be achieved by agreeing the design concept early in project development to eliminate late stage design changes; using standard design elements when practicable; resolving complex construction details before the project goes on site; avoiding clashes; taking advantage of intelligence and automation within the model to check design integrity and estimate quantities; producing fabrication and construction drawings from the model; and using data to control construction equipment.

Crowd behaviour and fire modelling capability enable designs to be optimised for public safety. Asset managers can use the 3D model to enhance operational safety. Contractors can minimise construction risks by reviewing complex details or procedures before going on site.

Integrating multidisciplinary design inputs using a single 3D model allows interface issues to be identified and resolved in advance of construction, eliminating the cost and time impacts of redesign. The model also enables new and existing assets to be integrated seamlessly.

Exact quantity take-offs mean that materials are not over-ordered. Precise programme scheduling enables just-in-time delivery of materials and equipment, reducing potential for damage. Use of BIM for automated fabrication of equipment and components enables more efficient materials handling and waste recovery.

BIM models contain product information that assists with commissioning, operation and maintenance activities – for example sequences for start-up and shut-down, interactive 3D diagrams showing how to take apart and reassemble equipment items and specifications allowing replacement parts to be ordered.

Members of the project team can feed back information about the performance of processes and items of equipment, driving improvements on subsequent projects.

ParsCo is a Certified General Contractor in the State of Florida with no limitations on construction. Whether it is a residential project or a 100 story high-rise tower, ParsCo can build it.

When working with a contractor make sure you understand what type of "license" they carry.

The Certified General Contractor License that Florida issues is one of the most difficult licenses to acquire.

All Rights Reserved © 2025. Site Designed By: CYber SYtes, Inc. Orchestrating the Web.